text1

description1

Our technologies are based on an agile development approach that combines innovation and efficiency to create customized solutions for our customers. By working closely with our partners, we offer the most up-to-date solutions on the market.

In the Aftermarket business segment, we develop vehicle-specific suspension applications. We customize our technologies for each vehicle model.

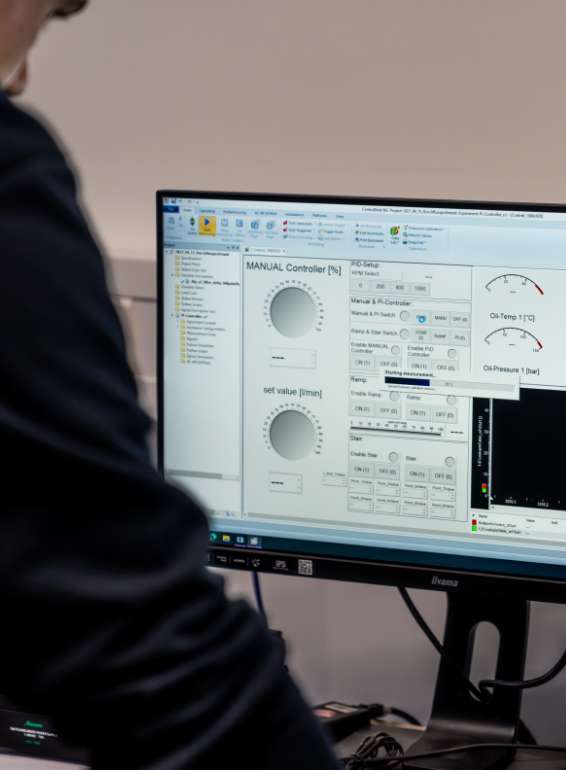

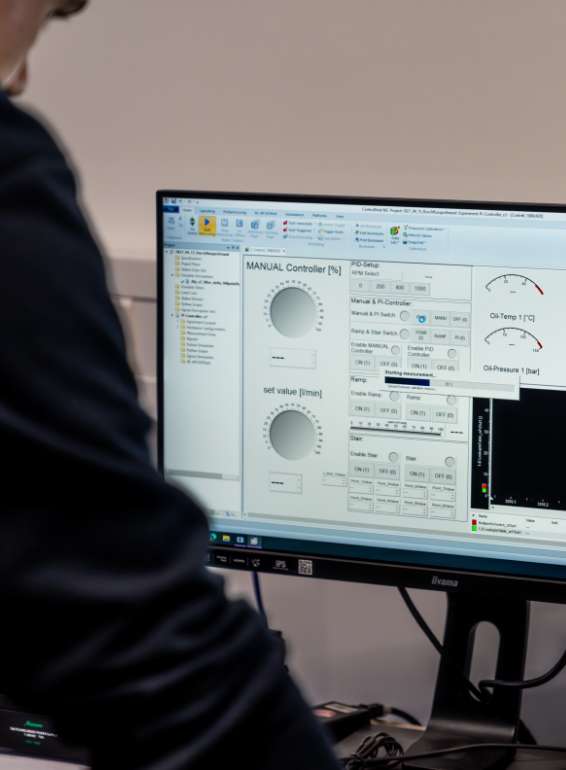

Our system developments offer customized solutions to meet the specific requirements of our customers. A broad-based development team accompanies each project in collaboration with the client. Thanks to a wide range of tools, we develop damper and valve systems, electronic components or software (low level/high level). An exemplary structure could look like this:

Our in-house developed tools are designed to fulfil the specific requirements and wishes of our customers in the best possible way.

Our Damper Tool enables the characteristic curves and adjustment ranges of a damper to be precisely matched to the requirements of the customer’s vehicle. Different setups are simulated and compared.

Our headquarters in Fichtenberg acts as a modern production facility for our world-renowned coilover suspensions and suspension components. By combining virtual simulation and real-world testing, we offer customers reliable and high-performance products.

Our virtual development methodology tools support customer projects from the initial idea to the finished product. We use cutting-edge technologies to ensure that customer projects meet the highest quality standards.

Precise analysis of our products results in optimum material distribution. The product becomes lighter or gains strength, depending on the customer’s requirements.

The customer benefits from efficient time savings as we can carry out virtual testing without the need for a physical prototype or vehicle.

The time we save reduces costs and allows us to use the resources we save elsewhere more profitably.

Design errors are detected early and can be rectified without losses.

Accurate simulations give everyone involved a better understanding of critical design parameters, even in areas that are inaccessible with traditional measurement tools.

Thanks to our versatile simulation tools, we save a considerable amount of material, time, and kilometers – a clear advantage for everyone involved.

description1

Mit einem Fahrdynamikprüfstand des BAR-Honda-F1-Teams positionieren wir uns als innovativen Vorreiter und wertvollen Entwicklungspartner innerhalb der Fahrwerksbranche.

Unser erfahrenes Team aus Ingenieuren und Technikern nutzt den Prüfstand, um Fahrwerksparameter (z. B. Aufbauresonanz-Frequenzen, Dämpfungsgrad, Nickverhalten, Aufbaubewegungen, dynamisches Fahrzeugniveau und Radlastschwankungen) gewinnbringend auszuwerten.

Wir prüfen eine elektromagnetische Baugruppe auf magnetische, elektrische und mechanische Eigenschaften. Anschließend wird dies in ein vereinfachtes CAD-Modell übertragen.

Unser Ziel ist, ein mechanisches Ventil um einen Elektromagnet zu erweitern. Hierfür schicken wir mithilfe einer Spule Strom in das Bauteil. Es entsteht ein Magnetfeld, das Pole ausbildet. Diese Pole ziehen einander an. Mit der Software JMAG erstellen wir einen digitalen Zwilling. Dadurch können wir vorhersagen und verstehen, wie die Energieumwandlung zur Kraft stattfindet.

Wir fügen dem digitalen Modell Daten über das Material, die geografische Lage des Materials und die Art des Bauteils hinzu. Das gibt uns Aufschluss darüber, wie sich das Material beim Durchdringen von Magnetfeldern verhält. Wir machen die Simulation mithilfe physikalischer Gesetze berechenbar.

Zur Prognose findet die sogenannte Diskretion statt. Das große, komplexe Gesamtmodell wird in kleine, weniger komplexe Teilmodelle aufgelöst. Jedes Teilmodell kann individuell berechnet werden und berücksichtigt die Daten der anderen Teilmodelle. Dadurch lokalisieren wir schneller Probleme.

Aus der Summe der Berechnungen bestimmen wir, wie sich die Teilmodelle gegenseitig beeinflussen und auf das Magnetfeld reagieren. Zum Schluss erfolgt das Post-Processing und die Validierung. Wir bereiten unsere Erkenntnisse auf und geben dem Kunden Handlungsvorschläge auf Basis der errechneten Daten.

Tool zur Simulation:

Der Begriff CFD steht für Computational Fluid Dynamics. Es werden strömungsmechanische Herausforderungen näherungsweise gelöst. Das Programm untersucht und visualisiert technische Abläufe innerhalb eines Bauteils.

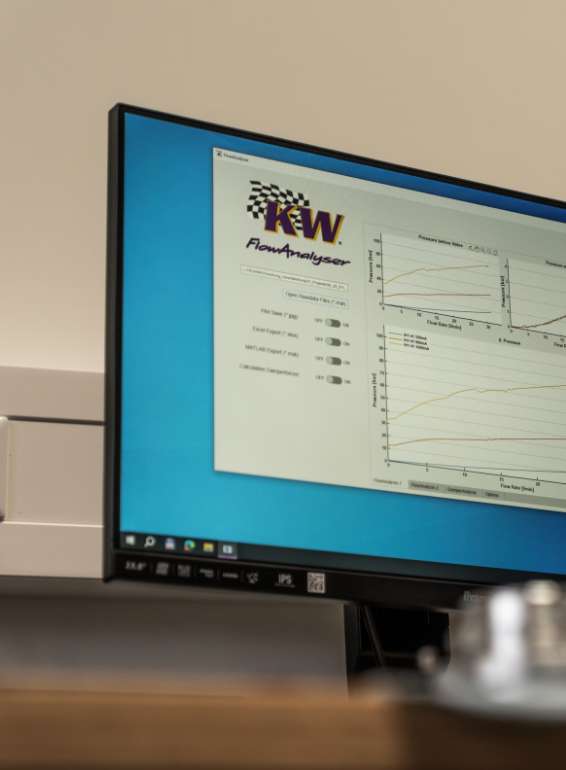

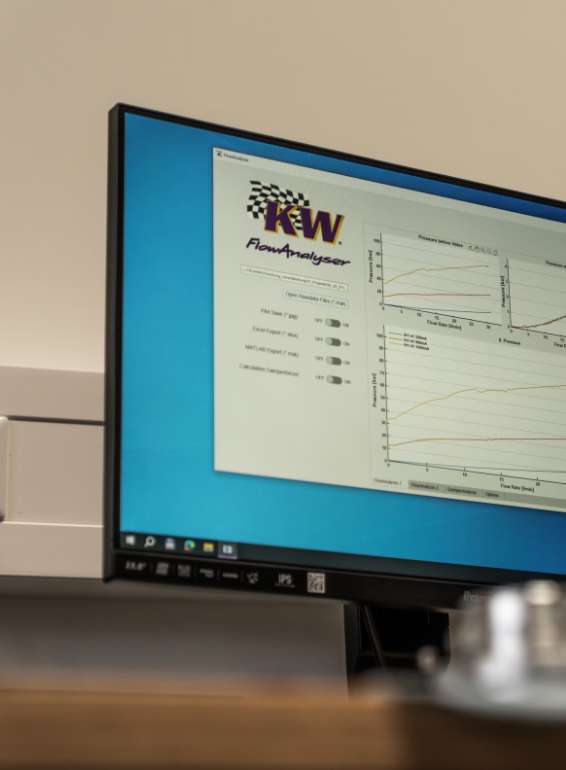

Um die Durchfluss-Druck-Kurve eines Druckstufen- oder Zugstufenventils anzupassen, messen wir den Druckabfall.

Wir messen die Geräuschbildung (Turbulenz), indem wir mithilfe eines analytischen Ansatzes den Lärm abschätzen, der durch turbulente Strömungen (ungleichmäßige Bewegungen des Fluids) erzeugt wird.

Die Messung des Unterdrucks (Kavitation) simuliert Dampfblasen innerhalb einer Flüssigkeit in Niederdruckbereichen. Diese treten an Orten auf, an denen die Flüssigkeit auf hohe Geschwindigkeiten beschleunigt wurde.

Tool zur Simulation:

Tool zur Simulation:

Our flow test bench enables precise analysis and optimization of valves before installation. By eliminating disruptive factors such as gas pressure, friction or leakage, we offer a detailed test of the valves.

During the development process, we attach great importance to a precise assessment of our products in order to deliver optimum results to the customer. With the help of objective data analyses and subjective driving impressions, we put the finishing touches to the product.

With the help of a road test and data logging, we get a picture of the interaction between the vehicle and the developed product.

Due to the large number of our application developments and years of professional experience in OE projects, we know what is important in the subjective evaluation of a damper setup. We evaluate our development work both on the basis of data and real driving impressions.

To ensure the long-term satisfaction of our customers, we carry out comprehensive long-term tests using servo-hydraulic test systems. This ensures that our suspension solutions remain fully functional even under intensive use.

For damper developments in road vehicles, we use a testing system from Schenk. Up to four test specimens can be tested simultaneously. The hydraulic cylinder reaches a speed of up to 1.75 m/s with a nominal force of 40 kilonewtons.

In the motorsport and off-road sector, we require greater assurance of product properties. We rely on a special test rig from Inova. Achievable speeds are over 7 m/s and a maximum stroke of 300 mm (nominal force at 100 kilonewtons). Hydraulic cylinders, a pump unit and pressure accumulator units are required. During peak excitation, the entire Powerpack excitation delivers up to 1,200 liters of hydraulic oil per minute. The power consumption of the motor is over 120 kW.

In addition to continuous operation, this test bench is also used to evaluate the acoustics and noise analysis. The customer benefits from products with maximum reliability.

With a driving dynamics test bench from the BAR Honda F1 team, we are positioning ourselves as an innovative pioneer and valuable development partner within the suspension industry. Our experienced team of engineers and technicians use the test bench to profitably evaluate chassis and damping parameters (e.g., body resonance frequencies, damping level, pitching behavior, body movements, dynamic vehicle level and wheel load fluctuations).

Simulation Tool: JMAG

To adjust the flow-pressure curve of a compression or rebound valve, we measure the pressure drop. We measure noise generation (turbulence) by estimating the noise produced by turbulent flows (irregular fluid movement) using an analytical approach. The measurement of negative pressure (cavitation) simulates vapor bubbles within a liquid in low-pressure areas. These occur in locations where the liquid has been accelerated to high speeds.

Simulation tool: ANSYS

We adapt our dampers to the desired target values even before production. The final curves are exported from the software. Subsequently, we can compare the simulation values with real measured values. Existing damping curves can also be imported and simulated.

Software: Virtual 4-Post

With component strength validation, we can determine before production whether the damper is strong enough. If the requirements are not met, we can pinpoint exactly which component needs to be revised.

Using topology applications, we optimize shapes based on algorithmic models. We determine the best possible material layout based on the load, condition, and constraint requirements.

In fatigue testing, we evaluate the reliability of our products. The analysis of fatigue failures helps us identify sources of errors and prevent product malfunctions.

Simulation tool: ANSYS

Marken | Heading #2 | Heading #3 |

|---|---|---|

| Simple content | Simple content |

Contact us on our social media accounts like Facebook or Instagram.

Kontaktiere uns einfach und bequem über unsere Social Media Kanäle.

Auf unseren Markenseiten findest du den Chat zu deinem Ansprechpartner.

KW automotive GmbH

Aspachweg 14

D-74427 Fichtenberg

Telefon:+49 (0) 7971 9630-0

Telefax:+49 (0) 7971 9630-191

E-Mail: info@kwautomotive.de

Vertretungsberechtigte Geschäftsführer:

Klaus Wohlfarth, Jürgen Wohlfarth

Registergericht:

Amtsgericht Stuttgart

Registernummer:

HRB 571255

Umsatzsteuer-Identifikationsnummer

gemäß § 27 a Umsatzsteuergesetz: DE 812 382 653

Verbraucherinformation gemäß Verordnung (EU) Nr. 524/2013:

Nachfolgend finden Sie den Link zur OS-Plattform der EU-Kommission: https://ec.europa.eu/consumers/odr/.

Unsere E-Mailadresse lautet: info@kwautomotive.de.

Streitbeilegungsverfahren:

Wir nehmen nicht an einem Streitbeilegungsverfahren vor einer Verbraucherschlichtungsstelle teil. https://ec.europa.eu/consumers/odr/.